14.06.13

|

| note the deformation. |

The

printing of the Potclays powder was a repeat of the red clay tests.

1:1:2, 1:1:3 and 1:1:4 mixtures were all successfully printed.

It's

important to leave the prints in the printer for 2 hours at the very

least before removing them. Even after 2 hours some were a little soft

and started to bend. Better to leave prints overnight, particularly if

more complex parts are being printed.

All the test bars were left to dry on top of a warm kiln overnight and this morning the excess powder was removed in the depowdering unit and the 950°C firing started.

The kiln was still around 100°C from a previous firing, but I decided to take it up slowly - 7 hours to 600°C, then 2 hours to 950°C with a 30 minute soak.

Even though we are awaiting the results of the firings, it seems a good opportunity to print a more complex form. My instinct tells me that that the 1:1:2 mixture will shrink a great deal and probably be the weakest, so I'm inclined to try the 1:1:3 powder. We will see...

|

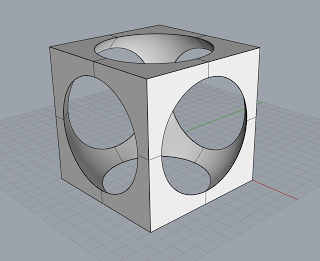

| 60mm test cube |

First of all I quickly created a cube with a sphere removed from the interior. This gives us a simple shape, probably impossible to slipcast that has a surface that just about covers every angle. So it makes a good glaze test, as well as testing the rigidity of the ceramic powder.

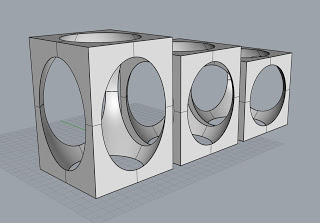

I actually set 3 versions printing, one as designed, the other two scaled one dimensionally to allow for possible deformation in the drying and firing.

|

| 80, 70, 60 mm test cubes |

I feel it is timely to look at this area, not just because we have new tools, but because our increasing reliance on 2-dimensional screens to engage with the physical world has the potential to detach us from the sensory experience and feedback we receive when we take the trouble to venture outdoors, smell those flowers in the garden, pick up that smooth stone or spot the woodpecker calling from a tree. You probably think I'm just being romantic, after all I'm one of the generation that bridges the digital divide, but when I hear about the exciting advances in augmented reality, where it will be possible to surround ourselves with virtual objects, rather than actual, physical stuff then surely it's time to question the very nature of our relationship with objects.

WIll we need to buy another pot or painting to decorate our homes when we will be able to simply download a holographic Ming vase?

Anyhow, I'll just leave that hanging in the air...